Eddy Current

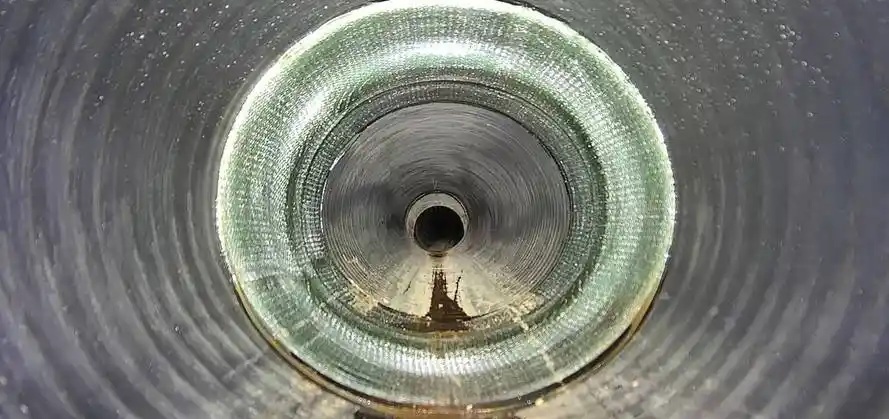

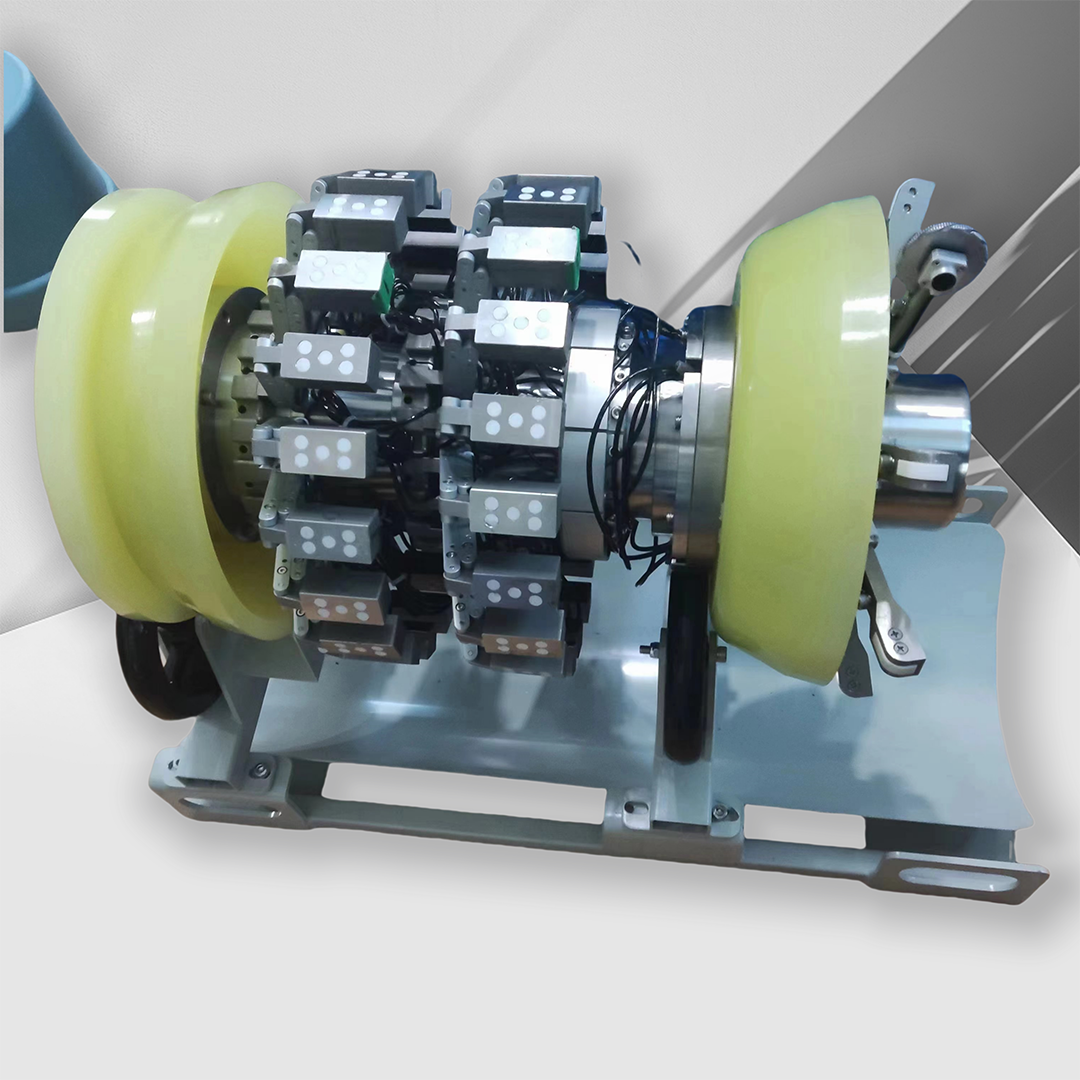

Many pipelines with low pressure and low flow rates are unable to undergo Magnetic Flux Leakage (MFL) inspection. To address this challenge, we have developed an advanced Eddy Current Inline Inspection (ILI) tool that provides an effective solution.

Our Eddy Current inspection tool is lightweight and operates at pressures as low as 5 kg. It can also integrate geometry inspection and IMU inspection, enabling a comprehensive assessment of pipeline routing, deformation, and internal metal loss in a single inspection run. Furthermore, our latest Eddy Current inspection technology extends wall thickness coverage up to 10mm, overcoming the traditional limitation of detecting only internal metal loss. This advancement allows for effective inspection of most pipelines up to 12" with a wall thickness less than 10mm, significantly enhancing the applicability of Eddy Current technology in pipeline integrity assessments.

Key Features:

1. Cover diameters from 6" to 40"

2. Utilize a dual sensor ring configuration, ensuring complete coverage of the inner wall of the pipeline.

3. High tolerance for sensor lift-off.

4. Low power consumption, and can inspect over 200KM in a single run, with customization available for longer distances.

5. High sensitive sensors, achieving a 100% detection rate for metal loss defects on the inner walls of carbon steel pipelines in a CNOOC blind test, recommended by CNOOC.